Coconut Processing

Coconut water is a refreshing drinks which also hygienic and nutritive. The white flesh is a calories rich extensively used for cookery in South India. From grated wet coconut kernel good quality oil as well as protein and carbohydrate can be extracted to prepare coconut honey. Undesirable flavour changes in desiccated coconut is due to oxidative rancidity of the oil. The residual cake after the oil has been extracted is used as cattle food.

The dried coconut meat is known as copra and is the source of coconut oil, which is used in enormous quantities for making fats for baking and confectionery. An important product used in the chocolate and confectionery industry is desiccated coconut. The nut is removed from the hard shell and the thin brown rind pared off. This must be very thorough or the finished coconut will be contaminated by flecks of brown. The pared nuts are then washed free of milk and skin residues and put through shredding machines, which give a milled product of varying degree of fineness. After shredding, the ground meat is subjected to a steam or hot water treatment to destroy salmonella and lipases and to reduce bacteria counts to low levels. The pasteurized meat is then dried on wire mesh belts by means of hot air, which reduces the moisture content to less than 4%. The critical moisture level of desiccated coconut is 5% and the product should be well below this to ensure good shelf life.

After drying, the desiccated coconut is put through a multiple sieving operation to produce the four main grades. Extra fine, macaroon (fine), medium and coarse. A variety of other coconut products is available to the chocolate and confectionery trade such as, moist white sweetened coconut, toasted coconut, creamed coconut and tenderized coconut.

Top quality desiccated coconut should be white in colour, free from foreign matter, and uniform in granulation against standard, and the expressed oil should have a free fatty acid content of less than 0.1%.

Extraction of Coconut Oil

The coconut is the most extensively grown and used nut in the world. About 10 million people in India and several million of people in other tropical regions depend on the coconut plant for their livelihood. India is the third largest coconut producing country of the world with an area of about 1.12 million hectares contributing to 18% of world production. India produces about 6000 million nuts annually. A whole coconut consists of 50% husk, 15% shell, 25% meat and 10% water.

The coconut shells contain 34% cellulose, 36% Lignin, 29% pentosans and 1% Ash.

COMPOSITION OF FRESH COCONUT KERNEL AND COPRA

Product |

Moisture % |

Fat % |

Protein % |

Carbohydrate % |

Mineral % |

Fibre % |

Kernel (wet) |

40-50 |

35 |

4 |

8-20 |

1 |

2 |

Copra |

6-7 |

62-65 |

7-5 |

15 |

2 |

3-4 |

Traditional method:

The coconut oil is traditionally extracted from copra. The copra can be obtained by separating the coconut meat from the whole coconut shell followed by sundrying and smoke drying for about 6 to 8 days. The copra is then chopped to small sizes and cooked by heating the small pieces of copra in a cooker for about 30 mins. The oil is squeezed out from cooked copra by an expeller and then filtered by a filter press.

Mechanical Extraction of Coconut Oil from the Fresh Coconut Meat:

The processes and operations involved in modern mechanical expression of coconut is given below;

- The coconut shells are cracked and the coconut meat is separated.

- The fresh coconut meat is chopped and sliced into thin flakes of the desired size.

- The thin flakes of coconut meat are cooked in a cooker by heating them at an elevated temperature for 90 mins.

- The oil is expelled from the heat treated cooked coconut meat (at a temperature of about 70°C) in an oil expeller.

- The oil is stored in an air tight container in a dark cool and dry place for a log and safe storage.

- The deoiled cake obtained from this process is suitable for human consumption.

Value Added Coconut Products

Coconut has been used as staple part of the diets of almost all Polynesian and many Asian people for centuries. It is used as food, as flavouring and made into beverages. Today’s young consumers depend heavily on conventional food. It is in this sector that coconut has a good chance to increase its use. The important products of coconut in our country are whole coconut (tender and mature), copra, toddy, neera, gur, coconut palm candy, sugar, vinegar etc. and few novel recipes like coconut boli, banana coconut cake. Coconut is a tasty food adjunct is well recognized. To use coconut in preparations, the consumer has to break the nut transversely into two, shred into gratings and then process further. On the other hand, if coconut gratings, its rich milk and even prepared foods are available as such on the shelves of the market, surely consumers, especially the younger generation will be generated to encouraged to use them in preparations much more.

Coco sauce: A tangy sauce can be prepared from coconut water with red chilli, onion powder and little vinegar.

Coconut lemonade: It was prepared by boiling coconut water, sugar and lemon juice. It is traditionally a popular drink in Kerala.

Nata-de-coco **: Nata from fresh liquid endosperm of the matured coconut is collected and filtered by using cheese cloth. It is pasteurized after adding 8 per cent sucrose, 0.5 per cent ammonium sulphate and adjusting the pH to 4.5 by adding acetic acid. The medium is developed by inoculating Acetobacter acetii at 10 per cent and incubated at room temperature for about two weeks. After two weeks a gel like mass developed with a film like layer on the top. The film is then removed and the mass is cleaned and cut into cubes. The cubes (nata) are further processed to improve the colour, flavour and taste by soaking it in sugar syrup. The nata can be used to decorate desserts, ice cream, puddings and fruit salad.

Coconut Kernel (or) White Meat**: The preservation and pickling of coconut was done by soaking the coconut kernels in brine solution maintained their colour, flavour, texture and taste and resembled like fresh coconut for 90 days. The salt and acid penetration in pickle is directly proportional to the concentration in the soak solution. The steeped coconut kernel were kept for 90 days under study, in which there was a remarkable reduction in reducing sugar, total sugar and free fatty acid content was increased gradually. The moisture content after storage ranged between 38.05 and 38.61 per cent.

The fresh coconut kernel could be preserved as long as for 3 to 6 months in the from of pieces and scrapings by steeping in a solution containing 4 per cent salt, acetic acid, sulphur dioxide and antioxidant. The product required washing in water prior to use.

Desiccated Coconut**: Desiccated coconut, the edible dried-out shredded coconut meat was prepared from fresh kernel of fully matured coconut and it is available in coarse, medium and fine grades and also in special grades such as threads, strips, granules etc. Good desiccated coconut is crisp, snow white in colour with a sweet, pleasant and fresh taste of coconut kernel. Desiccated coconut, a commercial product was manufactured from the white part of the meat after removing the brown parings. The meat is shredded or disintegrated and dried in hot air driers at 140-170oF to 2 per cent moisture content (fat 65-68 % and Solids nonfat 30-32%) and used in the manufacture of cakes, pastries and chocolates. Desiccated coconut is the disintegrated, white kernel of coconut processed under strict hygienic conditions and dried to a moisture content of below 3.0 per cent. It is a food product which is ready and fit for direct human consumption.

Products from desiccated coconut**: The matured coconut kernels were steam blanched and soaked in sugar syrup of 30o brix for a period of 48hrs.The drained pieces were sulphited for 20 min and dried in the cabinet drier at a temperature of 60oC for 8 h. Storage studies proved that sugar acts as an osmotic agent for the preservation of coconut. Osmotically dehydrated coconut was well suited for the preparation of products in the homes as well in commercial units.

The desiccated coconut powder (2%) or soy protein concentrate (SCP) (4.5%) was used in the preparation of mango bar, which increased the percentage of protein. The total soluble solids of pulp was raised to 30o brix with powdered cane sugar adding 0.6% citric acid and drying in an air cabinet drier at 63 + 2oC for 14h.

Coconut powder was used in the preparation of ragi based convenience mixes viz., sweetened and spiced mix. The other ingredients for sweetened mix were puffed ragi flour, sugar, beaten rice flakes, cardamom, coconut powder and puffed ragi flour, sugar, dehydrated coriander leaves, hydrogenated fat, coconut powder and groundnut for spiced mix. In sweetened mix, addition of beaten rice improved the colour but increased the rate of lipid oxidation while incorporation of coconut powder lowered the lipid oxidation.

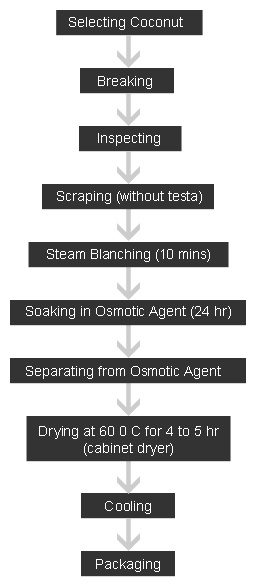

The value added products from coconut, such as dehydrated coconut (both savoury and sweet), ready-to-use coconut chutney mix, coconut kuruma mix, coconut rice mix and coconut burfi mix was developed. Acidified salt solution and sugar syrup were used as osmotic agents for the preparation of dehydrated coconut for savoury and sweet dishes. The dehydrated coconut (savoury) was prepared by soaking the blanched coconut scrapings in the soak solution containing 1.0 per cent salt, 1.0 per cent acetic acid and 250 ppm of SO2 without antioxidant (T1) and with antioxidant (T2) for 24 hr and dried in the cabinet drier at 60° C for 4 to 5 hr (upto 4.0 % moisture). The treated and dehydrated coconut samples were packed in 300 gauge polyethylene bag without vacuum and with vacuum and stored at room temperature to observe the storage behaviour.

Coconut Chips*:

Coconut chips, the thinly sliced crispy coconut meat which may be sweetened or salted and may come in handy as a ready -to- eat snack food. It was prepared by slicing the coconut meat of eleven to twelve month old nuts thinly into strands, soaked in syrup, drained and dried in a dryer or oven.

Coconut Crisps*:

Coconut crisp is prepared from the young coconut endosperm of nine to ten month old nuts. It is white in colour, has pleasant coconut flavour and does not leave any fibrous feeling after taste. It was processed by slicing the meat into 0.6-0.7mm thickness, blanched in boiling water, cooked in light syrup and then dried which is considered as a high energy food and of a good quality product.

Roasted young coconut*:

Roasted young coconut was prepared by a process in order to sweeten its water and tender meat as well as to enhance their flavour. The process consisted of preliminary steps and the nuts were boiled in a solution (2% sodium meta

bi- sulphite) for 20 min, dried and burnt for finishing touch and it was exposed to the fire for a minute or until the shell itself showed signs of burning. The fruit was kept at room temperature for 3 days or in the refrigerator for larger storage.

Honey roasted coconut*:

Honey roasted coconut, a sweet, thinly sliced crispy coconut meat, eaten as a snack food. Sliced matured coconut meats was mixed with honey sugar, margarine, sweeten condensed skim milk, molasses and salt and dried in oven for half an hour. Then it was agitated frequently for 15 min until it become crispy, cooled and packed.

Dehydrated sweet coconut*:

Young coconut meat was used for preparation of dehydrated sweet coconut. The coconut meat was washed with water and then soaked in coconut water, again washed with clean water. The meat was cut into pieces mixed with refined sugar and water in the ratio of 6:3:1 and boiled for 1 h or until it is dried, cooled and packed.

Dehydrated coconut chutney**:

Dehydrated coconut chutney using simple hot air drying technique was developed. It reconstitutes well in cold water and had all the characteristics of fresh chutney. The product had a shelf life of 3 months at 37oC and 6 months at ambient temperature when packed in flexible pouches.

Coconut milk**:

Coconut milk refers to the milky fluid, freshly extracted from the coconut kernel with or without added water and coconut cream to the high-fat cream-like material obtained from the coconut milk by either gravitational separation or centrifugation

Coconut milk was prepared by blending skim milk powder with

coconut milk, obtained from freshly grated coconut and pasteurized at 70-72oC for 10min. It contains 6 percent skim milk powder and 9.65 percent total solids (Agrawal, et al. (1991). Coconut milk, a generic term for the aqueous extract of the solid coconut endosperm, plays an important role in the cuisines of South East Asia as well as in other parts of the world.

Fermented beverage from coconut skim milk using different combinations of coconut skim milk and non-fat dry milk and the culture used was Lactobacillus bulgaricus. Based on sensory evaluation, 50 per cent of coconut skim milk: 50 per cent of non- fat dry milk ratio was the most acceptable formulation. The ready-to-drink fermented beverage concentrate (diluted at 1:3) contains protein (1%), fat (0.74%), sugar (18.70%) and water (79.25%). The fermented beverage concentrate was found to be stable even after 2 months of storage and coconut skim milk can be utilized successfully for the processing of cultured milk.

Coconut cream:

The concentrated milk extracted from fresh matured coconuts can either be used directly or diluted with water to make various curry preparation, sweets, desserts, puddings etc. Processed and packed coconut cream had a

shelf life of six months and once opened it should be stored in refrigerator for subsequent use. Coconut cream, a concentrated form of coconut milk, which is a convenient product prepared from mature and fresh.

Coconut syrup:

Coconut syrup, a translucent, free-flowing liquid was prepared by cooking coconut milk with an equal amount of refined sugar and di-sodium-phosphate equivalent to 0.25 per cent of the volume of the milk, until the mixture attained a TSS content of 68-70 per cent. The hot mixture was poured in sterile containers and sealed hermetically. It was used as a topping for bakery products or as a mixer in alcoholic drinks or may be diluted in water and used in cooking rice cakes and other delicacies.

Coconut honey:

Coconut honey is viscous, free-flowing syrup, similar to coconut syrup but less creamy and less nutty in flavour was used as topping for pancakes and waffles. One part of skim milk was mixed with ½ part of refined sugar and ½ part of glucose, and then blended with sodium alginate at 0.5 per cent as stabilizer. Coconut cream may be added to improve the flavour of the product. The mixture was heated for 15 minutes, homogenized and cooked with constant stirring in steam-jacketed kettle to a TSS of 75 per cent. It was poured hot into sterile containers and then sealed hermetically.

Sweetened condensed coconut milk:

Coconut skim milk was used in the preparation of sweetened condensed coconut milk. Powdered dairy skim milk was added for protein fortification and other ingredients were corn oil, coconut cream and sugar. The skim milk was first pasteurized for 30 mins at 80-90oC and mixed with other ingredients. The mixture was blended or passed through a colloid mill, and heated in a steam jacketed kettle with constant stirring to a TSS content of 68%. It was packed hot in sterile tin cans and cooled immediately in cooling tanks.

Coconut candy*:

Coconut candy was prepared from grated coconut meat mixed with coconut milk. The grated coconut was moistened with a portion of the milk. The remaining milk and the molasses were poured in a cooking pan, and the mixture was heated to boiling. Refined sugar was added and the mixture was cooked until it gets hardened when dropped into cold water. It was then poured in butter-greased pans, allowed to cool slightly, cut into desired sizes and individually wrapped in cellophane sheets.

Coconut milk powder:

Coconut milk powder was prepared by dehydrating the milk under controlled conditions. The composition of the milk was adjusted with fat percentage in the range of 50-60 per cent of the total solids. The emulsifiers and stabilizers were also added to the formulation. The most crucial step was the dehydration stage for which spray drier was employed at high temperature (around 180oC). Instant dehydration takes place converting each tiny droplet into microcapsules with fine droplet of the oil inside

Coconut flour**:

Coconut flour is a unique product prepared from coconut residue. Coconut flour, a by-product in the processing of coconut milk, can provide not only value-added income to the entrepreneurs but also a nutritious and a healthy source of dietary fiber for the consumers. It can be used as fillers, bulking agents and substitute for wheat flour, rice flour and potato flour at certain levels and incorporated into various food products like baked products, snack foods, steamed and extruded products. One by-product of coconut is the “sapal” from coconut meal, taken after extraction of the coconut milk. The “sapal” was made into coconut flour which contains dietary fibre. The utilization of coconut sapal may have some health benefits and may encourage the industry to produce value added products or functional foods which may help in the proper control and management of chronic diseases. This offers scope for utilization of coconut flour as a dietary component for diabetes. Low-fat, high fibre coconut flour, a unique product from sapal is a good source of dietary fiber. It is comparable with other cereal flour in terms of carbohydrate, fat and energy content and a good ingredient in nutraceuticals.

Tender coconut water: It is valued both for the refreshing drink and gelatinous kernel, which is a delicious food. The tender nut water is rich in potassium and minerals. Glucose content is maximum in seven months old nuts and hence the best stage for drinking. The dwarf coconut variety, Chowghat Orange Dwarf (COD) is a tender nut variety. The composition of tender nut water from this variety is as follows:

Particulars |

|

Quantity of tender nut water |

350 ml/nut |

Calorific value |

17.5/1000g of tender nut water |

Sugar |

7.1 mg/100 ml of tender nut water |

Potassium |

2000ppm |

Sodium |

20ppm |

Tender coconut water concentrate:

Coconut water concentrate was prepared using fresh coconut water collected under hygienic condition. Suspended solids and oil in the samples were removed by means of three way centrifuge. The removal of the solids and oil was necessary in order to minimize fouling of the membranes. The salts present in coconut water may be removed if desired, prior to concentration, to produce a very sweet product. This is achievable by passing the centrifuged coconut water through a mixed-bed ion exchange resin. The concentrate can be frozen or preserved in cans and used as base for the production of carbonated and non-carbonated coconut beverage.

Crystallized fruit was prepared using candied fruit coated with sugar or sugar crystals and allowed to deposit on it. Crystallized candy made with tender coconut kernel can be consumed as a snack. Tender coconut kernel in sugar syrup can be used as a dessert or incorporated in ice cream, custard or pudding.

Toddy:

Coconut toddy is obtained from the inflorescence before the flower fully develop. Sweet toddy is the unfermented fresh juice obtained by tapping. Toddy on fermentation becomes an alcoholic drink.

Coconut jaggery: Sweet toddy if carefully collected in sterile glass vessels remains unfermented for a considerable time. It can be strained and boiled down to the crystallizing point, to obtain 12-15 per cent jaggery with nutritional and medicinal value. The reducing sugars and minerals made it more nutritious and health friendly.

Coconut vinegar: Vinegar was produced from fermenting coconut toddy and was commonly used in the preparation of fish and meat dishes. If toddy was fermented for more than 24 hours and acidification was done for 10-14 weeks and the resultant was coconut vinegar.

FLOW CHART FOR THE DEHYDRATION OF COCONUT**

|

Snow Ball Tender Nut (SBTN):

Snow ball tender nut is a tender coconut without husk, shell and testa which is ball shaped and white in colour. Coconuts of 8 months age is more suitable for making SBTN in which there is no decrease in quantity of tender nut water and the kernal is sufficiently soft.

Matured Coconut Water:

Technologies have been developed for upgrading and bottling of matured coconut water as a soft drink using certain preservatives. Matured coconut water is been utilized successfully for production of vinegar using the technology developed at CFTRI, Mysore.

Virgin coconut oil:

Virgin coconut oil (VCO), extracted from fresh coconut meat without chemical processes is said to be the "mother of all oils". It is rich in medium chain fatty acids, particularly lauric acid and is a treasure trove of minerals, vitamins, antioxidants and is an excellent nutraceutical. It has about 50% lauric acids, having qualities similar to mother's milk, thus confirming its disease-fighting ability. When lauric acid enters human body it gets converted to Monolaurin, which has the ability to enhance immunity. Several studies have confirmed that this compound has the ability to kill viruses including herpes and numerous other bacteria. Its antiviral effect has the ability to considerably reduce the viral load of HIV patients. VCO is not subjected to high temperatures, solvents or refinement procedures and therefore retains the fresh scent and taste of coconuts. It is rich in vitamin E, is non-greasy, non-staining and is widely used in soaps, lotions, creams and lip balms. The health benefits of VCO are second to none; ranging from speeding up body metabolic system and providing immunity against a horde of commonly prevalent diseases.

Process: Coconut Kernels are first disintegrated into small pieces in a Disintegrator and then fed into a screw press for milk extraction. The oil is then separated from the water using a mechanical centrifuge. The result is a clear coconut oil that retains the distinct scent and taste of coconuts. Laboratory tests show that this is a very high quality coconut oil, with the lauric acid content being 47 to 52%.

Product specification

| Moisture % wt., Max. | 0.25 |

Colour in 1/4 cell Lovibond Y+5R, not Deeper than |

2.0 |

Acid value, Max. |

0.50 |

Unsap. matter % by wt., Max. |

0.8 |

Polenske Value, Min. |

0.8 |

|

|

Project Cost 20000 coconuts /day capacity)

| Land (cost variable) | 50 cents |

Building 6000 sq.ft. |

Rs.40 lakhs |

Plant and Machinery |

Rs.85 lakhs |

Preliminary and preparative expenses |

Rs.10 lakhs |

Contingencies |

Rs.2.50 lakhs |

Working capital (Margin Money) |

Rs.20 lakhs |

Machinery

| 1. Hammer Mill | 2. Bucket elevator |

3. Centrifuge |

4. Screw press |

5. Screw conveyor |

6. Crude coconut oil storage tanks |

7. Vibratory Sieve |

8. Micro filter |

9. Filtered oil storage tanks |

10. Volumetric filling machine |

- |

- |

Yield

| Raw material | 10000 coconuts |

Virgin Coconut oil |

600 litres |

Project Highlights (at 90% cap. Utilization)

| Sales turnover | 800 lakhs |

Net Profit |

160.0 lakhs |

IRR |

18% |

Break Even point |

65% |

Manufacturing units

- M/s.Golden Vintage Farmer’s Industry, Muringoor, Koratty.P.O., Chalakudy-680 308 ,CEO: K.A.Jogy,

Ph. 0480-2732858,3252858 Mob: 9447782851 - M/s. Mosons Extractions, Industrial Estate, Palayad, Thalassery, Kannur Dt.

Ph: 0490-3206825, Mob- 9388636181(Shri Anvar), 9447370956

E-mail: mosonsextractions@yahoo.co.in - M/s. Keratech Coconut Oil Manufacturing Company (P) Ltd., 1/332 B, P.O.Engandiyur, Trichur

Ph: 0487-2294515, 2296393,

Web Site: www.keratechindia.com - M/s.Srithara Agro Tech, G1, Tip Top Towers, Opposite Power Office Road N.G.O. Colony,

Ongole, A.P. PIN 523 002

Ph: 08592 282366, Mob: 9246463118

Coconut By-Products

1. Coconut shell charcoal:

This is obtained by burning the shell of fully matured nuts with a limited supply of air so that they do not burn away to ash but are only carbonized. it is used extensively for the manufacture of activated carbon. The charcoal has a high absorption capacity for gases and coloring matter and can be used as a refining agent, both as deodorizer and a decoloursier. It is also used in laundries and smitheries.

2. Activated Carbon:

Shell charcoal on activation is transformed into activated carbon which is having the ability to observe effectively even trace quantities of either unwanted or valuable liquids and gases. Activated carbon is used in solvent recovery processes, water and effluent treatment and the treatment of flue gas before discharge into the atmosphere.

3. By-Products from husk:

About 30 percent of the husk is fibre a 70 per cent is coir dust. Coir and coir products form the major output from the coconut husk. Coir pith is used as manure (After composting), mulch material and for making briquettes. The coir pith briquettes can be used as a substitute fuel in the place of fire wood for tile and brick industries.

4. Mushroom Cultivation Using Coconut By-Products:

Methods to cultivate mushroom using by-products of coconut as substrate have been developed at CPCRI, Kasargod. Among the cultivated mushroom, oyster mushroom belonging to Pleurotus spp. is the ideal one for cultivation on coconut by-products, because of the ability to utilize lignin rich materials and favourable climatic condition in the coconut growing areas.

Coconut bunch waste, leaf stalk, mixtures of leaf stalk + coir pith in 1:1 ratio and bunch waste + coir pith in 1:1 ratio were found to be better substrate for mushroom cultivation. On a average, mushroom yields 590 and 570 g per kg dry weight of leaf stalk and bunch waste in a cropping period of 73 and 60 days respectively. Polybags method of cultivation could be followed using 3% spawn applied by multi layering technique. This can be done in low cost sheds build with coconut materials such as plaited coconut leaves and coconut wood inside an adult coconut garden. Spraying 1% urea and 1% super phosphate helps to reduce the interval between flushes. Pleurotus eous, P. florida and P. sajor caju are the suitable species for cultivation in this method.

Other products

- Handicrafts items like ladles, forks, show piece, shell buttons, ice creams cup are prepared from coconut shells.

- The coconut wood is used for making wall panels, furniture’s

- Coconut leaves are plaited for thatching houses and sheds. It is also used for making baskets, temporary fences. Midribs of the leaves are used to make brooms.

Source

* - Post Harvest Technology Centre, TNAU, Coimbatore

** - Home Science College and Research Institute, TNAU, Madurai

http://img.alibaba.com/photo/11604133/RBD_Coconut_Oil.jpg

http://fromnaturewithlove.com/images/MilkPwdCoconut.jpg

http://z.about.com/d/thaifood/1/5/n/6/ccstep9.JPG

http://parrotisland.mainsecureserver.com/catalog/images/Coconut%20Chips1.jpeg

http://www.boreas-online.com/catalog/pics/Defatted_Desiccated_Coconut.jpg

http://www.marketmanila.com/wpcontent/uploads/2008/03/146.jpg

http://images.craveonline.com/article_imgs/Image/honey.jpg

http://pic.ccn.mofcom.gov.cn/export/14999/20070704143253.jpg

http://www.retrotuckshopsweetsdirect.co.uk/images/sweetpics%20024.jpg

http://www.boreas-online.com/catalog/pics/Defatted_Desiccated_Coconut.jpg

http://image.ecplaza.net/offer/g/ghuerto/4109238_s.jpg

http://www.abcstores.com/prodimg/COCONUTSYRUP-9Z.JPG

dailygirlblog.blogspot.com/2006/12/coconut-bu...

http://i192.photobucket.com/albums/z315/Archupritish/chutney.jpg

http://queenofthemeadowblooms.typepad.com/ 4.jpg