The Handheld Electronic Nose for gradation of Jasmine based on aroma characteristics is having the following features. The system is small handheld device, touch-Screen based user interface, integrated odour delivery unit, both battery / AC Adapter operated, data storage in SD Memory Card in FAT32 file system, results in Graphics Display, sensor array consisting of five (5) Metal oxide Sensors (MOS) and the report can also viewed through PC based report generation tool.

Electronic Nose system for gradation of Jasmine based on aroma characteristics comprises of two main components – (i) The Sniffing Unit and (ii) Data Processing Unit. The sniffing unit consists of the sensory and sensing unit. The sniffing unit is the odor capture and delivery system to the sensor array and the data processing unit is responsible for data acquisition from the sensor array through a proper signal conditioning circuit and the acquired data is processed to generate and display the Fragrance Index.

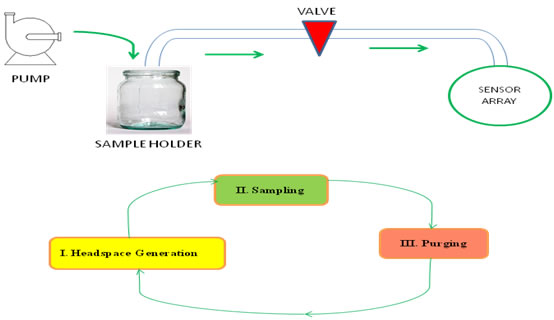

The experimental sniffing cycle consists of automated sequence of internal operations: (i) headspace generation, (ii) sampling, (iii) purging before the start of the next sniffing cycle. Initially these MOS sensors require heating for at least one hour to be stable. Heating is done by supplying 5 Volts to the heater coils of the sensors. This heating phase of sensors is referred to as Pre-heating.

The Metal oxide Sensors (MOS) sensors react to volatile compounds on contact; the adsorption of volatile compounds on the sensor surface causes a physical change of the sensor. The generation of aroma volatiles from the sample is called Headspace. Fixed air pressure is generated in the air-tight sample chamber to generate aroma volatiles. Sampling is the process in which the aroma volatiles generated during headspace are exposed to the sensor array in a controlled manner so as to maintain a constant operating condition all the time. A valve is made open and kept open for a fixed time so that aroma volatiles generated inside the sample holder may move to the sensor chamber at a fixed flow rate over a fixed period. During this entire period, changes on the electrical properties of all the sensors are recorded for analysis. |