|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fisheries :: Fish Culture |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fresh Water PrawnThe giant freshwater prawn is suitable for cultivation in tropical and subtropical climates. The most commonly cultured species in India is Macrobrachium rosenbergii. It is a hardy species by virtue of its ability to adapt to various types of fresh and brackish-water conditions. It accepts pelleted feed and has omnivorous feeding habit. The breeding takes place in low saline waters which is also needed for larval and post larval development after incubation. Breeding of M. rosenbergii takes place in estuaries. Though seed may be available in natural sources to a limited extent, for large scale culture there is a need to ensure regular supply of seed. For ensuring availability of quality seed in predictable quantity freshwater prawn hatcheries should be encouraged, technology for which is already developed. Freshwater prawn hatcheries are coming up in many states. The aquaculture production of giant freshwater prawn, Macrobrachium rosenbergii in India has shown a phenomenal increase in recent years that has increased from less than 500 metric tonne in 1997 to more than 30,000 metric tonne in 2003. The major bottleneck for the further expansion of the prawn culture is the lack of adequate supply of post-larvae (prawn seed) for stocking. The projected seed requirement for the development of at least two lakhs hectare of water area in the coming years is 10,000 million. Indian aquaculture has been evolving from the level of subsistence activity to that of an industry. This transformation has been made possible with the development and standardization of many new production and associated techniques of input and output subsystems. In recent years aquaculture has created great enthusiasm and interest among entrepreneurs especially for shrimp farming in coastal areas. Shrimp farming is capital-intensive activity and uncontrolled mushrooming growth of it has led to outbreak of diseases and attributed environmental issues calling for closure of shrimp farms. Although India has vast freshwater resources they are not fully exploited except for carp culture in limited scale. Fresh water fish culture employing composite fish culture technology has become popular for use in large number of tanks and ponds in the country. To meet the raw material required by the processing units for export demand there is urgent need to expand our production base. In addition it is always stressed that there is a need to utilise our natural resources productively to ensure the much needed food security. Scampi production through aquaculture in India

(Source: Marine Products Export Development Authority, 2005)

State wise production details of scampi farming in India

(Source: Marine Products Export Development Authority, 2005) Biology

The length of time that the eggs are carried by female freshwater prawns varies but is not normally longer than three weeks. The number of eggs that are laid also depends on the size of the female. Female prawns of M. rosenbergii are reported to lay from 80000 to 100000 eggs during one spawning when fully mature. Egg incubation time averaged 20 days at 28°C (range 18-23 days). Freshwater prawn eggs of this species are slightly elliptical, with a long axis of 0.6-0.7 mm, and are bright orange in colour until 2-3 days before hatching when they become grey-black. This colour change occurs as the embryos utilize their food reserves. As the eggs hatch, rapid movements of the abdominal appendages of the parent disperse the larvae. Freshwater prawn larvae are planktonic and swim actively tail first, ventral side uppermost (i.e. upside down). M. rosenbergii larvae require brackishwater for survival. The larvae go through 11 distinct stages before metamorphosing into post larvae. Stage I larvae (zoeae) are just under 2 mm long (from the tip of the rostrum to the tip of the telson). Larvae swim upside down by using their thoracic appendages and are positively attracted to light. By stage XI they are about 7.7 mm long. Newly metamorphosed post larvae (PL) are also about 7.7 mm long and are characterized by the fact that they move and swim in the same way as adult prawns. They are generally translucent and have a light orange pink head area. On completion of their larval life, freshwater prawns metamorphose into post larvae (PL). From this point onwards they resemble miniature adult prawns and become mainly crawling rather than free-swimming animals. When they do swim it is usually in a normal (dorsal side uppermost) way and in a forward direction. Rapid evasive movement is also achieved by contracting the abdominal muscles and rapid movement of the tail. Post larvae exhibit good tolerance to a wide range of salinities, which is a characteristic of freshwater prawns. Post larvae begin to migrate upstream into freshwater conditions within one or two weeks after metamorphosis and are soon able to swim against rapidly flowing currents and to crawl over the stones at the shallow edges of rivers and in rapids. In addition to using the foods available to them as larvae, they now utilize larger pieces of organic material, both of animal and vegetable origin. Post larval freshwater prawns are omnivorous can also be cannibalistic.

3. Site Selection for Hatcheries and Nurseries The site requirements for hatcheries and nurseries, which are normally associated with each other, are similar. Availability of Quality Water The hatchery and nursery should be located inland where there is ample supply of good freshwater. Saline water required for larval development can be transported and mixed with freshwater to attain the desired salinity. The quality of intake water, whether it is saline or fresh, is of paramount importance for efficient hatchery operation. Water quality is thus a critical factor in site selection. Hatchery sites should preferably be far from cities, harbours and industrial centres, or other activities, which may pollute the water supply. In all cases, water supplies need careful analysis during site selection, to determine their physical, chemical, and biological characteristics, and the extent to which these may vary daily, seasonally, or through other cycles. Special care is needed in hatcheries that are situated in or near areas where the use of pesticides, herbicides, and fertilizers is intensive. Ideally, freshwater should be obtained from underground sources. The brackishwater for use in M. rosenbergii hatcheries should be 12-16 ppt, should have a pH of 7.0 to 8.5, and contain a minimum dissolved oxygen level of 5 ppm. High levels of heavy metals, such as mercury (Hg), lead (Pb) and zinc (Zn), should also be avoided, since these are most likely to be caused by industrial pollution. Soil Characteristics The ideal soil for freshwater prawn culture should be clay-silt mixture or sandy loam comprising of 60% sand and 40% silt with good water retention capacity. There must be enough soil available for pond construction, whether the ponds are to be excavated or pond banks are to be erected above ground. Although supplemental food is given to freshwater prawns reared in earthen ponds, a considerable amount of their food intake is from natural sources. It is therefore preferable to site the farm where the soil is fertile, as this will reduce the need and costs of fertilisation. Freshwater prawn ponds should be constructed on soil, which has good water retention characteristics or where suitable materials can be economically brought onto the site to improve water retention. Pervious soils, which are very sandy or consist of a mixture of gravel and sand, are unsuitable unless the water table is high and surrounding areas are always waterlogged. Soils, which consist of silt or clay, or a mixture of these with a small proportion of sand, normally have good water retention characteristics. Peaty soils are not suitable. The clay content should not exceed 60%; higher clay content soils swell when moist and crack during the dry season, thus making repairs necessary. Other requirements for Hatchery sites In addition to having sufficient supplies of good quality water, a good hatchery site should also have: • A secure power supply, which is not subject to lengthy power failures. An onsite emergency generator is essential. Site Selection for Outdoor Nurseries and Grow-Out Facilities The success of any nursery facility or grow-out farm depends on its access to good markets for its output. Its products may be sold to other farms (in the case of nurseries), directly to the public, to local markets and catering facilities, or to processors or exporters. The needs and potential of each type of market need to be considered. It also important to consider other factors to ensure success, including the: • Suitability of the climatic conditions; Topography Farms must be close to their market so the road access must be good. Large farms will need to have local access for heavy trucks be able to reach the farm easily, for the delivery of supplies and the efficient collection of harvested prawns. A survey is necessary, to assess the suitability of a site from a topographical point of view. It is important to minimize the quantities of earth to be shifted during pond construction. Flat or slightly sloping lands are the most satisfactory. The ideal site, which slopes close to 2% (2 m in 100 m), allows good savings on earth movement. Care should be taken to ensure that pond sizes and alignments allow efficient construction, and at the same time permit good access and effective water supply and drainage. Climate The meteorological records such as temperature, the amount and seasonality of rainfall, evaporation, sunlight, wind speed and direction, and relative humidity should be studied for site selection. Avoid highly unstable meteorological regions. Strong storms and winds increase the risks of flood and erosion damage, and may lead to problems with transport access and power supply. Temperature is a key factor. Seasonal production is possible in semi-tropical zones where the monthly average air temperature remains above 20°C for at least seven months of the year. The optimum temperature range for year-round production is between 25 and 31°C, with the best results achievable if the water temperature is between 28 and 31°C. The temperature of the rearing water is governed not only by the air and ground temperature but also by solar warming and the cooling effects of wind and evaporation. The rate by which pond water is exchanged and the temperature of the incoming water are also important considerations. Rainfall, evaporation rates, relative air humidity and wind speed and direction also need to be investigated. Ideally, evaporation losses should be equal to or slightly lower than rainfall input, to maintain an approximate water balance. Mild winds are useful to promote gas exchange (oxygenation) between water and the atmosphere. However, strong winds can increase water losses by evaporation and may also generate wave action, causing erosion of the pond banks. Avoid areas where it is constantly cloudy because this makes it hard to maintain a steady water temperature, as it interferes with solar penetration. Periods of cloud cover of several days' duration may also cause algal blooms to crash, which in turn lead to oxygen depletion. Nursery Phase The nursery can be either indoor or outdoor. The selection of sites for indoor nurseries should follow the same pattern as for hatcheries. Site selection for outdoor nursery facilities should be similar to that for grow-out ponds. Holding Tanks After rearing freshwater prawns in hatchery, hold them until ready for stocking in ponds. Concrete tanks of 50 m3 are convenient for holding postlarvae (PL) prior to transport for stocking in ponds. Use nets suspended from floats in the tanks to increase the surface area available to the PL but this may make the normal operations of feeding, cleaning etc. more difficult.

Water quality and supply Freshwater is normally used for rearing freshwater prawns from postlarvae to market size. Water of 3-4 ppt salinity may be acceptable for the culture of M. rosenbergii. The reliability of the quality and quantity of the water available at the site is a critical factor in site choice. However, as in the case of hatchery water supplies, the absolute ‘ideal' for rearing sites may be difficult to define; a range of water qualities may be generally suitable. As for hatchery water, the level of calcium in the freshwater seems to be important. Growth rate has been reported to be lower in hard than in soft water. It is recommended that freshwater prawn farming should not be attempted where the water supply has a total hardness of more than 150 mg/l (CaCO3). Water quality requirements for prawn nursery and grow out

(Source: Food and Agriculture Organisation, 2002) Greenwater System of Freshwater Prawn Culture A more common alternative to the ‘clearwater' system for flow-through hatcheries is known as the ‘greenwater' system. In the greenwater system, a mixed phytoplankton culture in which Chlorella spp. is dominant is maintained in separate tanks. Its cell density is about 750000-1500000 cells/ml. A fertilizer solution in tap water is added to the tanks at least once per week to maintain the culture. This solution provides a mixture of 4 parts of urea to 1 part of NPK (15:15:15) garden fertilizer, applied at the rate of 185 g per 10 m3 tanks. Tilapia (Oreochromis mossambicus) is held in the tanks at the rate of about 1 per 400 l to graze on and control filamentous algae. Copper sulphate, at the rate of 0.6 ppm is added to the greenwater tanks once per week to control rotifers. The tilapia also helped to fertilize the culture. The sodium salt of EDTA (ethylene diaminetetraacetic acid) is included in the greenwater culture at 10 ppm as a chelator. The greenwater is prepared at the same salinity as the larval rearing water. Greenwater does not thrive at more than 12 ppt salinity. The greenwater culture is never used for larvae if the culture is more than three days old. Part had to be discarded or used for filling larval tanks and the rest diluted regularly to avoid phytoplankton ‘crashes' occurring in the larval tanks. Although the greenwater system may have some advantages, it is difficult to manage successfully and adds more complications to the hatchery process. For this reason, most commercial freshwater prawn hatcheries now use clearwater systems of management, whether they are flow-through or recirculation. Semi-Closed, Two Phase Clear Water Larval Rearing Technology Central Institute of Freshwater Aquaculture has developed and standardized a two-phase clear water technology for larval rearing that is suitable for non-coastal hatcheries. This technology can be suitably modified to suite other locations also. Healthy mother prawns (bearing grey eggs on their pleopods >50 g) are selected from the broodstock pond/tank and disinfected with 0.3 ppm copper sulphate or 30 ppm formalin for 30 min. Mother prawns are then stocked @ 100-150 g/m2 (2-3 nos of ~ 50 g female) in brackishwater (salinity of 5‰) and reared till hatching. Tanks are checked daily for appearance of larvae. Once hatching occurs it may continue for 24-48 h. The spent female is removed from the tank and released back to the broodstock pond. The salinity of the larval rearing medium is then increased to 12‰ and the rearing is continued in the same tank. In the first phase the larvae (Zoea I) are stocked in cylindro-conical tanks at a high density (200-300 larvae/l). About 50% of the medium is usually exchanged every other day with fresh medium of identical salinity. The larvae are reared for about 10-12 days in this phase. In the second phase, the advanced larvae are stocked in larger tanks with a greater surface area at the rate of 50-80 per litre and reared till metamorphosis. About 50% of the medium is exchanged every alternate day. The freshly hatched Artemia nauplii are given as live food to the prawn larvae, 4-5 times per day in the early stages (Stages II to V or VI) and later, once during late evening in combination with wet larval feed which is usually given during day time. The brine shrimp nauplii are fed to the prawn larvae at the rate of 5 to 50 nauplii per larva per day. About 2 kg of Artemia cysts are required to produce one-lakh post-larvae. Wet larval feed (egg custard, minced fish/mollusc flesh; protein level> 50%) is fed @ 50-200 mg/larva/day depending on the larval stage. The wet feed is given from 8 am till 2 pm at one-hour interval. The larval rearing tanks are cleaned daily by siphoning off excess food particles and metabolic waste from the bottom of the tank. This is done after stopping aeration, preferably in the evening hours before exchange of water and introduction of live food (Artemia nauplii). Daily monitoring of temperature, salinity, pH and dissolved oxygen levels is essential to maintain the water quality at optimum levels. The optimum ranges of water quality parameters for successful seed production are given below.

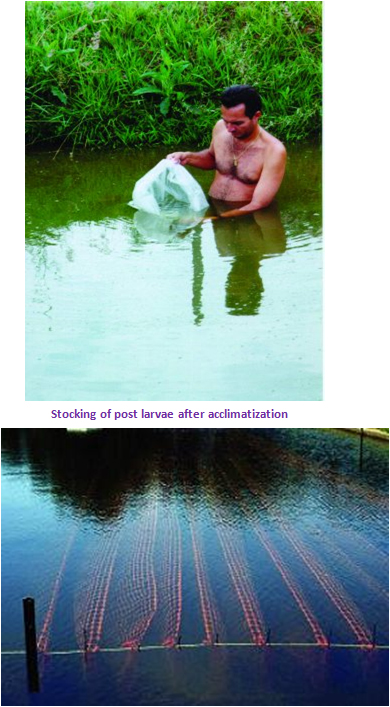

The appearance of first post-larva is usually observed 20 days after hatching, normally between 22 and 26 days (at 28-32°C) and 90% larvae metamorphose within next 10 days. The seed production normally ranges between 35-40 per litre and the cycle lasts for 35-40 days. The post-larvae are gradually acclimatized to the freshwater and reared at high densities (2000-5000/m2 ) for 10-15 days in hatchery. The post-larvae are fed with formulated diet @ 100% of the biomass per day. After a week post-larvae are suitable for stocking in grow-out ponds.

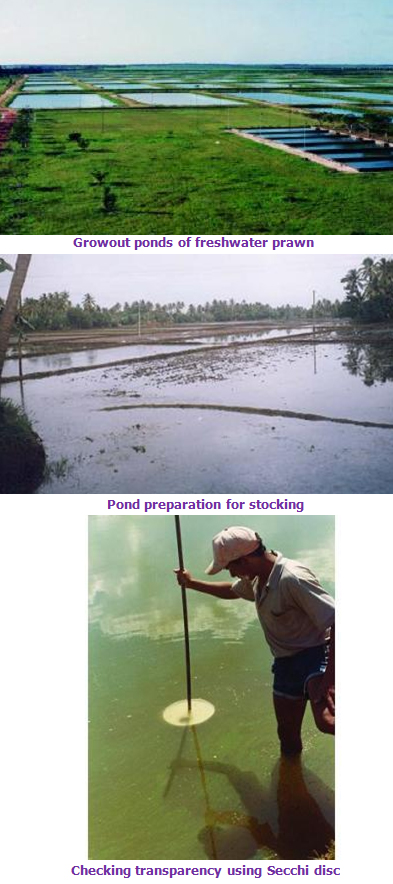

Basically there are three different farming techniques used for Macrobrachium rosenbergii : A) Extensive Freshwater Prawn Culture Extensive culture means rearing in ponds (but also in other impoundments such as reservoirs, irrigation ponds and rice fields), which produce less than 500 kg/ha/yr of freshwater prawns. They are stocked, often from wild sources, with PL or juveniles at 1-4/m2 . There is no control of water quality; the growth or mortality of the prawns is not normally monitored; supplemental feeding is not normally supplied; and organic fertilisation is rarely applied. B) Semi-Intensive Freshwater Prawn Culture Semi-intensive systems involve stocking PL or juvenile freshwater prawns (usually from hatcheries) at 4-20/m2 in ponds, and result in a range of productivity of more than 500 kg/ha/yr and less than that defined as intensive in this box. Fertilisation is used and a balanced feed ration is supplied. Predators and competitors are controlled and water quality, prawn health and growth rate are monitored. This form of culture is the most common in tropical areas. C) Intensive Freshwater Prawn Culture Intensive culture refers to freshwater prawn farming in small earth or concrete ponds (up to 0.2 ha) provided with high water exchange and continuous aeration, stocked at more than 20/m2 and achieving an output of more than 5000 kg/ha/yr. Construction and maintenance costs are high and a high degree of management is required, which includes the use of a nutritionally complete feed, the elimination of predators and competitors, and strict control over all aspects of water quality. This form of culture is not recommended in this manual because it requires more research, particularly on size management. Based of the management practice employed there are four different management systems being adopted for freshwater prawn farming in India. System 1: The Continuous System This involves regular stocking of PL and the culling (selective harvesting) of market sized prawns. There is no definable ‘cycle' of operation and the ponds are therefore only drained occasionally. One of the problems of this form of culture, which can only be practiced where there is year-round water availability and its temperature remains at the optimum level, is that predators and competitors tend to become established. Also, unless the culling process is extremely efficient, large dominant prawns remain and have a negative impact on the postlarvae, which are introduced at subsequent stocking occasions. This results in a lower average growth rate. The decline in total pond productivity (yield) that has been observed when this system has been used for a long time is, however, not confined to this management system and may also be a function of genetic degradation, as discussed elsewhere in this manual. This results in less and less satisfactory animals being stocked. System 2: The Batch System At the other extreme to the continuous system is the batch system, which consists of stocking each pond once, allowing the animals to grow until prawns achieve the average market size, and then totally draining and harvesting it. This reduces predator and competitor problems. However, the problem known as Heterogeneous Individual Growth (HIG) remains. This term (HIG) refers to the fact that freshwater prawns do not all grow at the same rate. Some grow much faster, tend to become dominant, and cause stunted growth in other prawns. System 3: The Combined System This provides the advantages of reduced predator and competitor problems of the batch system with the cull harvesting employed in the continuous system, to reduce the problems of HIG. In the combined system, ponds are stocked only once. Cull harvesting starts when the first prawns reach market-size (the exact size depends on the local, live sales, or export market requirements). This removes the fast-growing prawns for sale, leaving the smaller ones to grow, with less HIG impact. Eventually, after several cull-harvests, the ponds are drained and all remaining prawns harvested. The total cycle usually lasts about 9-12 months in tropical regions, depending on local conditions. This system is recommended in this manual. System 4: The Modified Batch System This is a more complex management regime involving three phases. After 60-90 days in a 1000 m2 nursery pond stocked at 200 to 400 PL/m2, 0.3-0.5 g juveniles were harvested and stocked at 20 to 30/m2 empty ‘juvenile' ponds. After another 2-3 months, seine harvesting of these juvenile ponds begin and this is repeated every month. These harvests removed animals of 9 to 15 g, which were then stocked into ponds with existing populations of small prawns. The juvenile ponds were themselves then either converted to adult ponds, to allow remaining animals to grow to marketable size, or were drained and refilled for further use. Further advantages is obtained if post larvae are held longer in the nursery ponds and then graded into at least two size groups before stocking into juvenile ponds. Ponds need to be well maintained during the farming period. Special care should be taken for prevention and treatment of pond bank erosion and the maintenance of water inlet and outlet structures, particularly the filters. Pond surface area can be increased by placing rows of netting, suspended from floaters and weighed down with sinkers, across the pond. Without using substrates to increase productivity, a stocking rate of about 4 juveniles/m2 (40 000/ha) is recommended for the monoculture of Macrobrachium rosenbergii in temperate zone ponds. There are some advantages in using larger juveniles for stocking. For example, it has been demonstrated that increasing the average stocking weight at 4 animals/m2 from 0.17 g to 0.75 g increases production at harvest by nearly 30%. However, this stocking size advantage does not apply indefinitely; research has shown that stocking 3 g animals did not improve production because the animals matured too rapidly. Grading nursed juvenile prawns before stocking also has significant advantages. In temperate zones it has been found to increase average harvest size and total pond production. Size grading is a way of separating out the faster growing prawns and lowering the suppression of growth that they cause to other prawns; it can also result in improved feed conversion ratios (FCR). These types of management make prawn production feasible in smaller, deeper ponds, which were previously considered unsuitable. Polyculture Culture Farming Macrobrachium species in combination with single or multiple species of fish, including Tilapias, Common carp, Chinese carps, Indian carps, Ornamental fish etc are common. The inclusion of freshwater prawns in a polyculture system almost always has synergistic beneficial effects, which include:

Prawn-fish polyculture systems are therefore normally batch-harvested. The addition of prawns to a fish polyculture system does not normally reduce the quantity of fish produced. On the other hand, the addition of fish to a prawn monoculture system markedly increases total pond yield but may reduce the amount of prawns below that achievable through monoculture. Integrated culture The wastewater from ponds containing prawns being reared in monoculture or polyculture with fish can be used for the irrigation of crops. Prawns can also be reared in paddy fields, without depressing rice production. The introduction of freshwater prawns reduces the area devoted to rice paddy (because deeper areas where prawns can shelter when the rice field is dry have to be provided). It also reduces weeding costs (prawns eat weeds) and fertilization costs.

It is necessary to maintain an adequate phytoplankton density, to provide cover and control the growth of weeds in freshwater prawn ponds. This is done by encouraging the growth of phytoplankton. However, it is often unnecessary to fertilize, because this is rapidly achieved by the feeding regime. However, ponds built in a sandy-clay soil may require fertilization for this purpose. Where necessary, 25 kg/ha/month of triple superphosphate will keep the water green. Benthic fauna are very important features in the ecosystem of freshwater prawn ponds, forming part of the food chain for prawns. Fertilisation to encourage the development of benthic fauna is therefore recommended. Animal manures have been used for this purpose (e.g. 1000-3000 kg/ha of cattle manure). The types of feed used in freshwater prawn farming vary widely and include individual animal or vegetable raw materials and feed mixtures prepared at the pond bank; both of these are generally referred to as ‘farm-made feeds'. In addition, commercial feeds designed for freshwater prawns are available. Freshwater prawns are omnivores and, so far as is known at present, their nutritional requirements are not very demanding. Some farmers utilize commercial feeds designed for marine shrimp in freshwater prawn nurseries or during the first few weeks of the grow-out phase when prawns are stocked as PL. Marine shrimp feeds have a much higher protein content than is needed for freshwater prawns, so cheaper commercial feeds that have either been specifically designed for freshwater prawns or for a species of fish (e.g. catfish) must be used in grow-out ponds stocked with nursery-reared juveniles, or substituted as soon as possible in those stocked with PL. The prawns are fed daily with formulated pellet diet (2-3 mm size) @ 10% of the biomass initially and then reduced to 3% of the biomass towards the end of the culture period. Many different ingredients could be used in your farm-made feeds, either individually or combined into ‘compound feeds'. Commercial feeds for freshwater prawns tend to use ingredients, which are available in large quantities; many of them are global commodities, such as fish meal or soybean meal. In addition to ‘trash' fish, molluscs and prawn wastes form valuable animal protein sources. Pond water stands at risk of pollution if individual raw materials (not made into a mixed and bound compound feed), especially with wet materials (such as trash fish and beef liver) are used. Compounded feeds, especially when they are water-stable, cause less problems of this type. Compounded chicken and pig feeds, either unmodified, or re-extruded through a mincer with trash fish or prawn meal, have been used in freshwater prawn farming. Feed formula for Freshwater prawn

There can be no exact general recommendation for daily feeding rates, because these depend on the size and number of prawns (and, in a polyculture system, fish) in the pond, the water quality, and the nature of the feed. The feed should be broadcasted in the pond as mentioned above. Spread the feed around the periphery of the pond in the shallows, which are good feeding zones. Check trays 3-4 nos may be kept in different corners of the pond to check the consumption of food.

Health, Predation and Disease Continuous exchange of a small proportion of the water is the normal way of maintaining good water quality. However, some farmers change water more suddenly every two weeks, and in much larger proportions, because this tends to make the prawns moult. The more that moult (and are therefore soft-shelled) at the same time, the less potential losses there may be due to cannibalism. Low dissolved oxygen should be suspected if prawns begin to crawl out of the ponds or congregate at the edges of the pond in daylight. If this problem occurs, flush the pond. Very high pH levels in freshwater prawn ponds can cause prawn mortalities, both because of the direct effect of the pH itself and because of the greater solubility of waste ammonia at high pH. High pH is often caused by dense phytoplankton blooms. Major problems that may arise during culture are mortality of the stock due to low dissolved oxygen in the pond water. Heavy plankton bloom, very low water level and lack of water exchange leads to low dissolved oxygen levels. Continuous rainy/cloudy days precipitate this problem. Immediate water exchange or aeration of ponds during night hours prevents this problem. Development of bottom algae due to high transparency of water is another problem during monoculture of prawns. To avoid this problem always maintain transparency in 30-40 cm range by frequent fertilization. Predation is one of the greatest problems for any aquaculture enterprise, including freshwater prawn farming. Predation is caused mainly by other aquatic species, birds, snakes and humans. Normally, insects (mainly dragonfly nymphs), carnivorous fish and birds are the most serious predators in freshwater prawn farming. Major diseases known to affect freshwater prawns, and their symptoms

(Source: Food and Agriculture Organisation, 2002) Prevention and Treatment of freshwater prawn diseases

(Source: Food and Agriculture Organisation, 2002) Basically there are two methods of harvesting: cull-harvesting drain harvesting. Harvesting time depends partly on growth rate and the size of animals you want to sell. This, in turn, depends on your market requirements. It also depends on the pond management technique chosen. Cull-harvesting is used to harvest market-sized animals from the pond at intervals and removes the faster growing prawns. In tropical ponds cull-harvesting usually starts 5-7 months after PL have been stocked, or sooner if juveniles have been stocked. After cull-harvesting commences, you should totally seine each pond once per month or partially seine it twice per month (i.e. seine half the pond twice per month or all of it once per month). Take out the market-sized animals and sell them. Keep the smaller ones and soft-shelled animals in the pond for further growth. After about 8-11 months, drain the pond and sell the whole harvest.

Drain Harvesting The method and efficiency of drain harvesting depends on the design of the pond. As with any other method of harvesting, speed is important and harvesting should start very early in the morning while the temperature is cool. You can partially draw down the pond water level during the night before harvesting commences.

Marketing prawns alive will usually generate a better price but, it also increases handling costs. Marketing them successfully in this way depends on the ability to keep them alive during transport and display, and to present undamaged, healthy prawns in an attractive way. Marketing your freshwater prawns fresh or frozen Prawns can be sold fresh (chilled) if they are going to be consumed within 5 (preferably 3) days. Prawns, which are not expected to be sold within 3 days, should immediately be frozen. Freezing should take place when they are fresh, not after they have been on ice for several days. Frozen tails have a longer shelf life than whole prawns. Whole frozen freshwater prawns will turn ‘mushy' if they are frozen and held above -20°C, or if they are thawed and refrozen. It is recommended that prawns to be stored for long periods be held at -30 to -35°C. Tails which are frozen in ice blocks may be stored for over a year and still be very satisfactory, although a maximum of six months is recommended. Glazing or vacuum packing significantly prolongs the useful life of frozen prawns. While vacuum packing requires elaborate processing facilities, not available to small farms, glazing is quite simple: a very thin mixture of syrup and water prevents oxidation. Economics The detailed economic analysis of larviculture and farming of freshwater prawn Macrobrachium rosenbergii in India is given in below. Economics of seed production of M. rosenbergii of 10 million capacity

* The capital requirement for variable cost may be only 25-30% of the above shown amount, as the income from sale of post-larvae after one cycle may be ploughed back for the subsequent cycles. (Source: National Bank for Agriculture and Rural Development) Economics of grow-out production of prawn

(Source: Central Institute of Freshwater Aquaculture) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

© All Rights Reserved. TNAU 2009-15. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||